At EJ Prescott, our customers have developed a strong respect for the high-quality products and materials we've brought to their attention over the years. But one aspect of our company that many customers may not be aware of is our sister companies. In particular, one of the areas where Team EJP has continued to work to provide the best possible experience for our water utility clients is in tool development. Towards that end, our sister company, New Concept Tools, was developed to provide the best options for our clients.

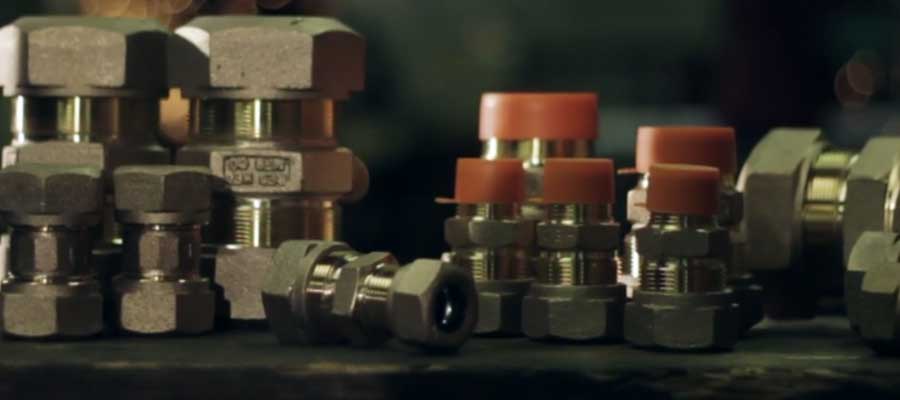

Team EJP has worked hard to provide our customers with the best quality water utility fittings, fixtures and supplies. But what you may not realize is that our sister company, RedHed Brass Manufacturing, has been gaining ground recently, especially following the Flint lead crisis. Why? RedHed produces 100% lead-free brass fittings, exceeding current lead-free regulations. This has made them very popular in the water utility industry recently. Here's more about our sister company and how it can benefit your water utility.

When your culverts are aging or beginning to fail, rehabbing them can seem like a difficult, expensive process. You need to dig up old culverts, remove and replace them, and then repair any property disruption or damage. But what if you had a fast, easy process available for rehabilitating your municipality's or agency's old culverts? Slip lining provides you with an easier, less labor-intensive way to rehabilitate your aging culverts without any significant digging, dangerous trench operations or risk of failure. Here are some of the benefits you can expect to see when slip lining your old culverts.

Let's face it - there are few things that mess up a water utility crew's day as much as much as water showing up where it shouldn't be. Though commonly caused by broken pipes, water travel can also cause serious issues for your water utility. Whether water is entering where it shouldn't, or draining from where you need it, we're dedicated to helping you find the right solutions for every project and problem you encounter. Here's a quick overview of our new High Density Polyethylene (HDPE) trench dams and how they can help you get the job done.

When you need to reinforce or rehabilitate sewer or water lines, it can seem like options are limited. You can dig up and replace the aging pipe; slip line the pipe with PVC or HDPE; or add an epoxy lining to reinforce and support the existing pipe. Even though many water utilities are familiar with the first option and may have heard of the second option, very few are familiar with what epoxies are, how they work and what benefits they can bring to your system. Here's a quick look at Warren Environmental's products and how they can help reinforce your existing system - buying extra time before you need to replace pipe systems.

When your water utility is getting ready to install new lines or replace aging ones, one of the best materials we've run into for the job is HDPE. High-density polyethylene pipe delivers strong, long-lasting performance with a light weight and price tag. Conservatively expected to last 50-100 years by the Plastic Pipe Institute. HDPE is making waves in the waterworks industry. Here's why you should investigate its potential further.

When it comes to laying in lines for your water utility, there are many options available, but which one will work best? At Team EJP, we're pretty enthusiastic about the promise of HDPE pipe systems. But we realized that some of our clients aren't as familiar with this relatively new material as we are. We kept receiving a lot of questions about what it can or can't do, how do you install it and is it really the best option for your water utility, so we put together this quick reference to help you decide if it's a good match for your needs.

When you're running new water lines, nothing can seem as time consuming as trying to get a successful pressure test. The cap takes forever to get into place, and then quite often pops loose before you've had a chance to get the entire line up to the pressure needed to test for leaks or weak points. Fortunately, the developers at Alpha are always creating better products for the water utility industry, and their restrained end cap can help make your pressure testing process easier and faster with superior results. Here's how:

In upstate New York, the town my husband grew up in had water lines passing under a nearby river. The old pipes had developed leaks over the years, and as the river would reach an algae bloom stage each summer, the river water that leaked into the pipes made the water taste horrible. It was so bad, you could taste it through the syrup in fountain drinks or in the ice used to cool the bottled water that was sold in restaurants. Though this situation wasn't of the level of the recent Flint lead crisis, there's no doubt that the local water utility received many a complaint about the situation. One solution that would have worked well in both situations? Heat fused HDPE.

When you need to educate yourself or your water utility crew, it can seem as though there are few real resources available that work with your schedule and timeframe. Fortunately, continued improvements in technology are providing new opportunities in the form of webinars. An online seminar, these options provide you with greater flexibility for increasing your waterworks knowledge. Here's some information about what's available and what Team EJP has upcoming to meet your educational needs.