When you're working around heavy machinery, there's always a risk of danger from the weight and power of these big machines. Because heavy equipment is designed to handle very large volumes or loads of material, they can have issues with line of vision and can cause accidents as a worker is caught in or under the machinery. For this reason, it's vital that they be operated properly and with a crew that is alert to everything going on around them. Here are some basics of how your heavy equipment should be operated and how your crew should work around it safely.

Though winter may seem a long ways off, it's important to remember that winter's cold, frozen pipes and house fires from portable heaters are just a few short months away. How do you keep your municipality's waterworks department running smoothly through the cold? Part of the process is to have a checklist you start on now so that everything is in place instead of panicking and having to pay extra to get what you need in a cold-weather emergency.

When you have a paving job that needs to get done, it's easy for it to either get delayed or go over budget. How do you get the job done effectively and efficiently? One option that many contractors are putting into effect are the stabilization and paving products from Tensar. Two of the most popular products they offer is GlasGrid and Geogrids. Let's take a solid look at each product and what their advantages and disadvantages are for your situation.

If it wasn't hot, it wouldn't be summer. Unfortunately, that means you need to watch out for your crew to ensure they don't become dehydrated on the job or succumb to heat-related illnesses and injuries. Here's a quick guide to keeping your crew moving without endangering their condition.

Ductile iron pipe is the industry standard in supply main piping. But sometimes, in some situations, you need a tougher option. Many municipalities facing problematic soil conditions or corrosion issues are starting to turn to zinc-coated ductile iron pipe to ensure a longer-lasting supply main while lowering your overall maintenance and replacement costs. But how does it work and why is it superior to plain ductile iron? Here's the basics.

*Updated 07/23/2020*

When you deal with water distribution lines on a regular basis, you know two things for certain: sometimes they leak and meters aren't always correct. How can you get around these two issues and stop losing revenue for your operation? One solution is large meter testing, which helps you determine where the problems are in your system and prevents low flow losses from industrial or institutional clients. Here's more information on the process:

We've all seen it happen. A poorly set up hydrant installation goes badly and damages the hydrant, the worker or both. How do you safely handle a heavy hydrant on damp ground with improvised equipment? The simple answer is that you don't. Safety needs to come first, not last. Here are some tips on how to safely handle hydrants during installation or removal to best ensure the condition of the hydrant and the safety of the crew:

Many waterworks training workshops and seminars tend to rehash the same old information, which is why they're often so poorly attended. At Team EJP, we're committed to creating dynamic changes for the waterworks industry that lead to serious cost and time savings for your organization. For that reason, we've developed our own series of Know How seminars. These day-long seminars provide you with real information on changes in our industry. Industry leaders, waterworks officials, Team EJP experts and select vendor representatives give you the latest techniques, management processes and technology without all the hype. Here's a bit more on these valuable seminars - put them on your calendar today to get in on the 2017 seminar series:

In the beginning, PEP Transportation was founded by Peter Prescott with a single tractor trailer in 1980. Dedicated to provide water, sewer and drain product transportation throughout New England. As a sister company PEP saw a lot of demand based on their business with EJP. This lead to fast growth in PEP, requiring additional units to be brought online to keep up with demand.

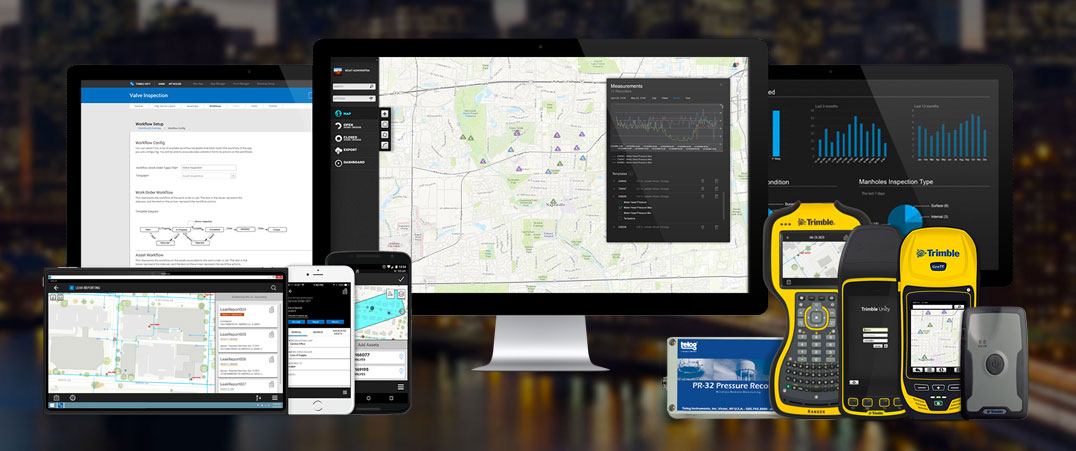

With the prevalence of smart meters, Internet of Things sensors and the advent of the digital workflow, there's no doubt that technology in waterworks is here to stay. But how do you coordinate all the separate pieces to work together effectively? Many businesses, organizations and waterworks departments have begun to implement the Trimble Unity platform to improve their connectivity and efficiency, but still have questions about which apps should be used with the software to make it even more effective. Towards that end, we've written a review on AFC Mapper, which helps bridge construction, mapping and maintenance workflows to improve your crew's efficiency in the field.