Preparing Your Town's Water Infrastructure for Winter

- Home

- Team EJP Blog

- Preparing Your Town's Water Infrastructure for Winter

- Jan 21, 2015 7:28:00 AM

- Everett J. Prescott

An estimated 700 water main breaks need repair each day in the U.S. primarily due to the country's aging water infrastructure. The EPA reports that 30 percent of pipes delivering water to 100,000+ people are between 40 and 80 years old, with another 10 percent of those pipes even older than those estimates.

Further complicating the maintenance and repair of our aging water infrastructure is the fairly recent addition of underground cables--cable, electrical, fiber--that weren't there just 20 years ago. Even newer water infrastructures possess numerous components that were previously missing and therefore, did not need to be maintained, everything from pressure reducing valve stations and post indicator valves to detector check assemblies, riser assemblies and fire department connections.

How Subfreezing Temperatures Impact Water Mains

- Stress dramatically increases on pipes with only a 10-degree change in air temperature. Frozen ground above pipes also intensifies the pressure exerted on pipes.

- When the water temperature is less than 40 degrees, pipes may become more brittle and prone to cracking.

- Since drops in water temperatures lag behind changes in air temperature, pipes may wait several days before bursting after a cold snap.

- Frost in the soil surrounding pipes can cause excessive expansion. Additionally, consistently cold (or hot) temperatures can expedite ground expansion and contraction more readily.

- Older, degraded and corroded water infrastructures are five times more likely to experience the damaging effects of winter weather than recently installed or upgraded (in the last 15 years) infrastructures.

While the majority of breaks happen to water mains constructed of cast iron, nearby construction excavation activity and previous pipeline breaks can promote soil erosion around water mains which facilitate breaks as temperatures edge close to freezing. Most older pipes lack cement lining and will corrode rapidly both inside and outside. Also, pipes exhibiting smaller diameters tend to have a greater risk for breaking, not only in winter but in extreme heat as well. Pipes with diameters less than 10 inches typically experience "circle" breaks while larger pipes will suffer "split" breaks.

Winter Weather Strategies to Protect Your Town's Water Infrastructure

Acoustic (Sonic) Leak Detection

Pressurized water pipes that develop leaks allow water to flow rapidly into the surrounding soil, causing the pipe to vibrate at the point where the leak is occurring. Emission of sound waves produced by this vibration is transmitted by leaking pipes and is audible at remotely located valves (contact points), as well as in neighboring pipe extensions and the water jet near the leak. Acoustic leak detection devices provide signal processors capable of suppressing extraneous sounds so that leak vibrations are displayed as minimum sounds. Additionally, some acoustic detection equipment offers plastic pipe location technology that improves detection of sound waves emitted by newer pipes.

Pressurized water pipes that develop leaks allow water to flow rapidly into the surrounding soil, causing the pipe to vibrate at the point where the leak is occurring. Emission of sound waves produced by this vibration is transmitted by leaking pipes and is audible at remotely located valves (contact points), as well as in neighboring pipe extensions and the water jet near the leak. Acoustic leak detection devices provide signal processors capable of suppressing extraneous sounds so that leak vibrations are displayed as minimum sounds. Additionally, some acoustic detection equipment offers plastic pipe location technology that improves detection of sound waves emitted by newer pipes.

Upgrade Cast Iron Mains

Before winter, consider having large cast iron mains rehabilitated by cleaning interiors and reinforcing them with cement linings to minimize corrosion and extend the life of such pipes. Cleaning of cast iron pipes can be done properly by pulling a mechanical scraper through the main to remove tuberculation. After the main is flushed clean, cement mortar can be sprayed onto the interior of the main until it is uniformly thick enough to prevent further degradation. Prior to placing rehabilitated mains back in service, they need to be flushed again, disinfected and tested for purity by your local health department. There are alternatives to traditional mechanical pigging that are less damaging to the pipes such as: Chemical cleaning solutions can be performed on isolated lines (Blue Earth), as well as ice pigging (pumping ice slurry through the lines). See and example here.

Robotic Pipeline Testing

Electromagnetic Inspection

Robotic pipeline testers detect and measure external and internalmetal corrosion, metal loss and other anomalies that may indicate a breach in your town's water infrastructure. Moreover, the regular use of pipe inspection robots also provides critical information needed to support integrity management programs and to ensure compliance with federal safety standards pertaining to pipeline systems. In addition, robotic pipeline testing offers a better alternative to hydrostatic testing, since breaks or ruptures are not instigated with robotic technology. While hydrostatic testing's "all or nothing" technique may be applicable in some cases, it does not always detect active corrosion areas.

By detecting and quantifying compromises in pre stressing wires that strengthen concrete pipes, electromagnetic inspection of your town's water infrastructure will provide system operators with accurate data on the distribution, location and amount of wire breaks existing along a specific pipeline. Advantages to electromagnetic testing include the ability to prioritize pre-winter repairs, reducing cold weather pipeline ruptures that could result in lengthy shutdowns and quickly identifying unique pipe segments suffering broken bars or wire breaks.

Keep Pipeline Resources Ready and Available When Repairs are Needed

Vital to maintaining the integrity of your town's water infrastructure is the ability to make repairs as quickly and effectively as possible by always having an adequate inventory of pipeline accessories available. Some of these accessories should include:

- Alpha restrained joints, couplings and end caps

- Repair clamps

- Tapping sleeves

- Dismantling joints

- Valve insertions

- Sewer/manhole adaptor gaskets

Be aware that high-density polyethylene pipes react differently to frigid weather and should be repaired using special HDPE pipe fittings to avoid recurring leaks or ruptures.

Be prepared for Main & Service breaks!

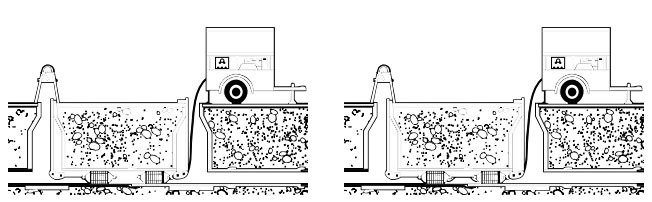

The Romac Alpha is a wide range, restrained coupling that installs in about three minutes and can be used to couple and restrain pipe ends with different diameters within the range. The Alpha provides..

- Wide range covers DI through IPS PVC pipe diameters without having to change components

- One piece, stab-fit installation

- New yellow grippers are HDPE compatible

- Cast components are high strength ductile iron