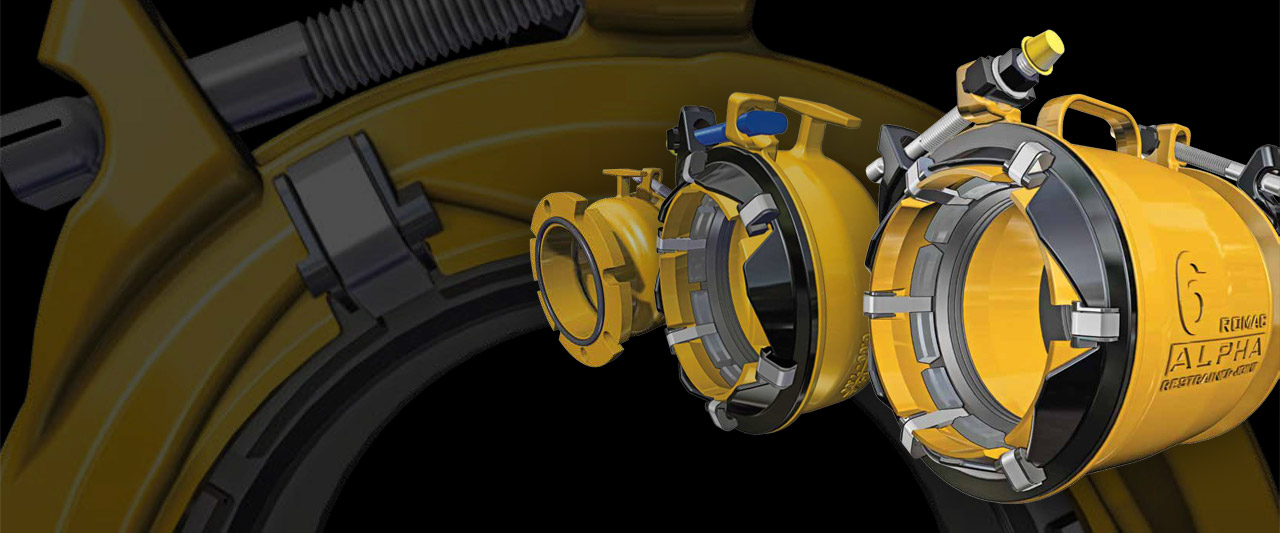

When you need to get a job done quickly, it's important to have the right materials on hand to be able to do so. What if you could use a single coupling for a wide range of materials that still delivers solid results and years of reliable performance? If you want this level of economy and efficiency for your water utility, it's time to become familiar with Romac Industries Alpha Restraint Couplings. Here are some details to help get you started on learning about these high-quality restraint couplings.

When you're joining up different types of pipe, have you ever wanted a single, simple coupler that will quickly and easily join them without a lot of special orders, hassles and hope that the final product is actually the right one for your needs? Meet the Romac XR501. Designed to provide superior adaptability and flexibility in the field, it provides you with an easier solution to keep on hand in your workshop for emergencies. But how exactly is it different than the other products on the market? We're glad you asked.

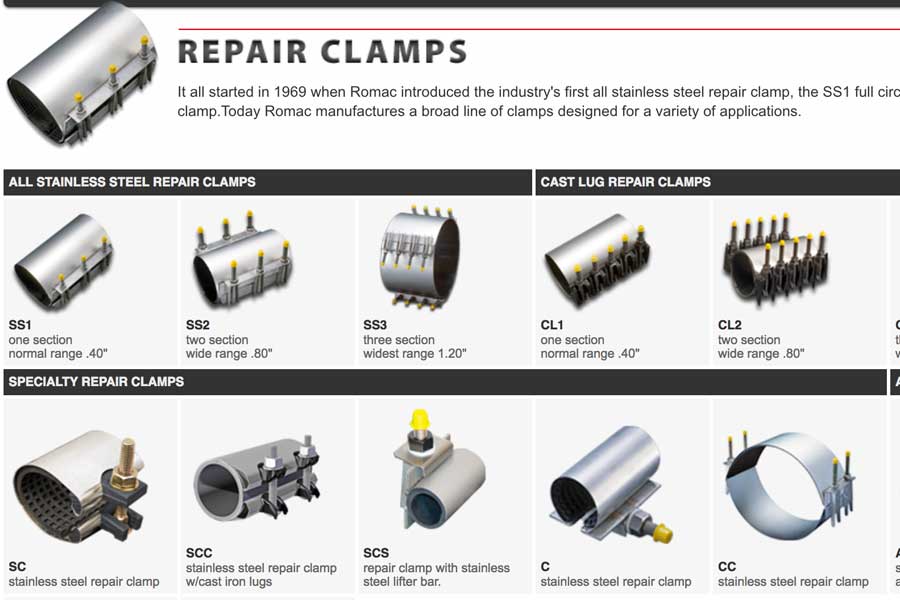

When you're facing an emergency situation, having the right tools and materials on hand to make repairs are vital to how well the situation turns out. But which ones will help you get the job done? Most utilities know the go to item in most cases is a repair clamp. Repair clamps are all about handling the un-expected quickly and with minimal interruption in service. Maintaining an inventory of repair clamps to accommodate the pipe sizes and types in your system is the best way to make sure you and your team are ready the next time a leak turns up.

*Updated April 9th, 2020*

When you tie into an existing water main, you can either shut down the whole system to insert the tap or wet tap it while the system is still under pressure. Many municipalities are not familiar with how wet tapping works, so they use the same old technique they always have: shutting down the whole system. Unfortunately, that technique creates a lot of extra work, with pipe dewatering requiring that the water be tested for bacteria once it's turned on again according to regulations under the Safe Drinking Water Act. It also requires that a boil order be activated for all customers receiving water through that service. With wet tapping, you simply go on with your day. Let's look at what wet tapping is, how it works and the benefits and drawbacks of this technique.

According to the Water Main Break Clock, an average of 850 water main breaks occur on a daily basis in the U.S. That's more than one every two minutes. A particularly spectacular one at UCLA spewed out over 20 million gallons of water, flooding the campus as a 12" cast iron water main installed over 85 years ago gave way. Why do they do so much damage? Old iron pipes in corrosive soil eventually rust away, leaving a geyser or a mud hole behind for your maintenance workers to fix.

When you're working on directional drilling, it can seem as though there are as many questions as there are answers. But when it comes to the piping you use for directional drilling when you're trying to prevent traffic disruptions and surface repairs, two main contenders go to the top of every list: ductile iron pipe and polyethylene pipe. But what are the advantages and disadvantages of each pipe variety? Which situations do they work best in and which should be avoided? In this post, we'll take a good, solid look at each pipe variety and how they hold up in different situations.