*updated 08/21/2020*

Updating your hydrants and valves can dangerous and time-consuming. Your crew is at risk, with worksite accidents being the nightmare of your water utility, impacting your crew's morale, increasing your worker's comp insurance, slowing don work and potentially increasing your liability. Having your water system down for extended periods of time while replacing hydrants leaves your area open to fire damage as firefighters are forced to rely on tanker trucks.

When you're working in the water utility industry, sometimes you run into a specific situation where only a particular type or style of pipe will get the job done. There are several effective ways to build your piping system in plant and station projects. Choices are made by the ease of installation and repair. Design conditions require rigidity or flexibility. The joint you choose is an important factor in the system's performance as a whole. Here's a quick overview of several of the fabricated pipe options QWP has available to help you get the job done.

When you're considering tapping a large diameter water main, it can be difficult to figure out how to go about the process. Though small taps are fairly common, those taps that are larger than 2" can create their own unique challenges. Fortunately, you have a few different options available when you need to make a large diameter water main tap. Here's a quick overview to help you get started.

Water line chlorination and de-chlorination is a part of relatively common operations, but can still be a pain to work into the schedule. Fortunately, you have alternatives that still have your lines treated properly and in a timely manner. Team EJP has put together a great program to help you manage your line chlorination and de-chlorination process. Here are the details.

When you're running new water lines, nothing can seem as time consuming as trying to get a successful pressure test. The cap takes forever to get into place, and then quite often pops loose before you've had a chance to get the entire line up to the pressure needed to test for leaks or weak points. Fortunately, the developers at Alpha are always creating better products for the water utility industry, and their restrained end cap can help make your pressure testing process easier and faster with superior results. Here's how:

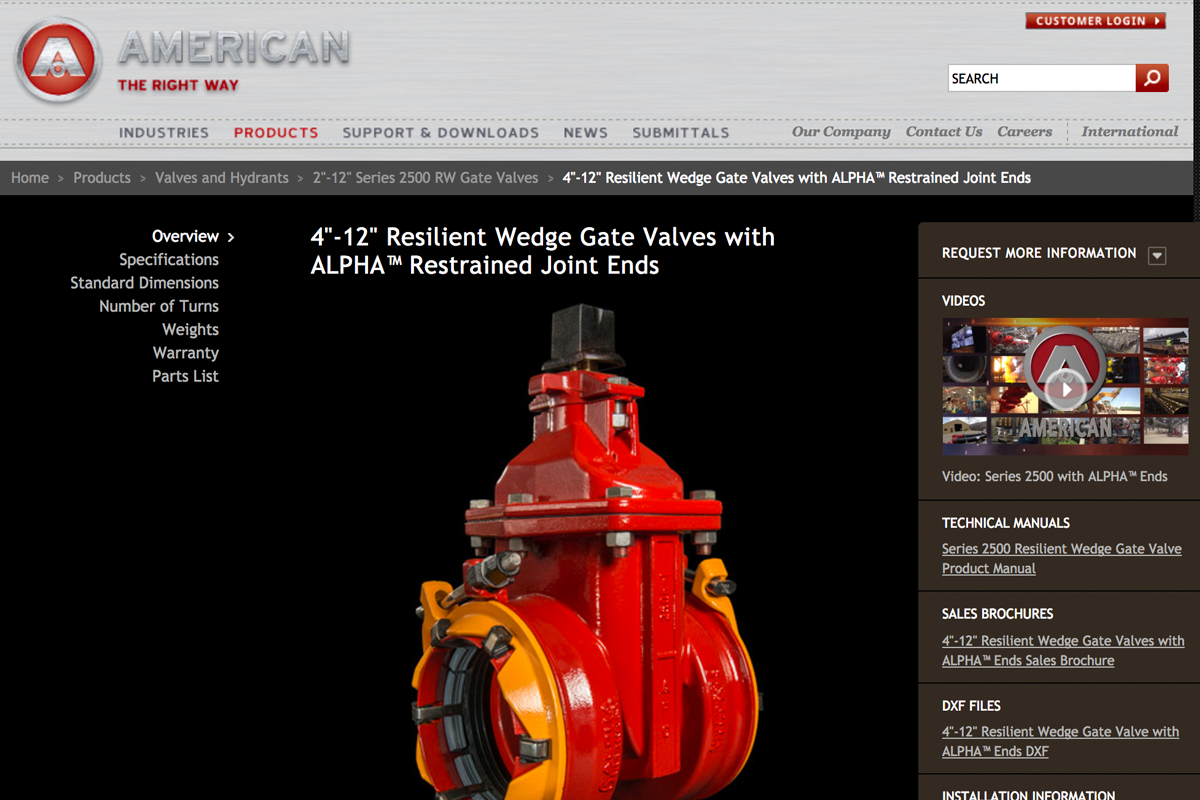

We've all had valve installation jobs we'd rather just forget about. They seem to take forever, have a ton of bolts to secure, require serious blocking to reach those awkward bolts at the bottom and often require a minimum of two people to get them in place and installed properly. This takes a lot of time that you don't always have! Team EJP understands your frustrations. Fortunately, there's a much easier option available from one of our partners. Learn more about the Alpha valve below.

Ductile iron pipe is the industry standard in supply main piping. But sometimes, in some situations, you need a tougher option. Many municipalities facing problematic soil conditions or corrosion issues are starting to turn to zinc-coated ductile iron pipe to ensure a longer-lasting supply main while lowering your overall maintenance and replacement costs. But how does it work and why is it superior to plain ductile iron? Here's the basics.

*Updated 07/23/2020*

Flint, Michigan has been making the news lately, and not in a good way. With lead contamination in the water affecting between 6,000 and 12,000 children and 10 people dead from Legionaries' Disease, the government is scrambling to address the issue, but nearly a year into this event following the change in water supply sources, how will they recover from this? Flint is facing many of the same problems municipalities across the country are seeing, as the economy continues to slowly climb out of the recession. Old water supply lines are leaking, corroding or otherwise in need of replacement and money is tight. Fortunately, there are a variety of options available that are both affordable and safe. Here's our look at replacement piping and which situations they work in.

Though federal regulations provide strict limitations to what compounds are acceptable in potable water, the increasing interest in water filtration and potential water contamination often leaves customers curious or concerned about what's in their drinking water, often above and beyond what is really concerning. Though the primary concerns deal with lead or bacteria, some waterworks customers are starting to ask questions about the safety of zinc in their water supply. Here are some easy answer to common concerns raised by waterworks customers over the use of zinc in water pipes, fittings and fixtures.

When you're dealing with corrosive soils, how can you ensure that your ductile iron pipe is protected from corrosion and premature failure points? Like any type of naturally-occurring aspect of the environment, soils vary greatly and can be very corrosive, causing problems with your pipe systems if proper precautions are not made. But how can you decide what needs to be done? Here is some additional information on corrosive soils, how to mitigate the corrosiveness of the soil and what type of pipe coating works best to reduce the problem.